Our offer of coats

The coats of STATON company – nano-layer and multi-layer reach high hardness, low friction coefficient, high resistance against abrasive and adhesive weari and high heat resistance.

Coat types produced in STATON Turany:

TiN – Titanium Nitride

It is the most common hard, abrasion-resistant coat. It provides for reducing the friction, improving the chemical and heat resistance, and reducing the built-up edge, primarily at soft steel machining. TiN is suitable for coating the tools made of sintered carbide and tool steels– drills, milling cutters, screw-taps, reamers, cutting tips, cutting tools, shearing tools, benders, moulds, etc. Thanks to its rich gold color it is extensively applied also as a decorative coating.

TiAlN – Titanium Aluminium Nitride

It is harder than TiN and its heat/oxidizing resistance is higher than 800°C. It is used for machining the materials of higher strength and at more difficult cutting conditions. TiAlN is suitable mainly for monolithic hard-metal milling cutters, drills and cutting tips.

KTRN – Composity Temperature Resistant Nitride

KTRN is suitable for applications where the high chemical and heat resistance (over 900°C) is required. KTRN is an universal coating, which is suitable for machining both easily and hardly machinable steels, non-corrodible steels, cast iron and is used in extremely hard cutting conditions. It is used for monolithic hard-metal milling cutters, drills and cutting tips for CNC machining centres.

CRONAL – Chromium Aluminium Nitride

Cronal is a especially developed coat for extremely hard cutting conditions at machining the heat-treated steels.

| COAT | Coat thickness | Hardness (GPa) | Friction coeff. | Heat resistance (°C) | Coating temperature |

| TiN | 1 až 4 | 23 | 0,5 | 600 | 450 – 500 °C |

| CrN | 26 | 0,75 | 600 | ||

| TiCN | 27 | 0,2 | 400 | ||

| TiCN multi | 27 | 0,2 | 400 | ||

| TiAlN | 32 | 0,6 | 800 | ||

| AlTiN | 2 až 4 | 33 | 0,65 | 900 | 450 – 500 °C |

| CARBOTIL | 36 | 0,4 | 750 | ||

| Alu CARBO | 35 | 0,4 | 800 | ||

| CRONATIL | 34 | 0,6 | 900 | ||

| CARBOCRONAL | 35 | 0,5 | 800 | ||

| ALUTICROL | 2 až 4 | 34 | 0,6 | 900 | 450 – 500 °C |

| CARBOALUN | 35 | 0,5 | 850 | ||

| KTRN I. | 36 | 0,45 | 1000 | ||

| KTRN II. | 37 | 0,4 | 900 | ||

| CRONAL I. | 36 | 0,45 | 1000 | ||

| CRONAL II. | 2 až 4 | 37 | 0,4 | 950 | 450 – 500 °C |

| CALCRON | 36 | 0,4 | 1000 | ||

| CALCRONIS | 37 | 0,45 | 1100 | ||

| CALCROL | 36 | 0,35 | 1000 | ||

| SICRAL | 37 | 0,3 | 1000 | ||

| CrN – L | 1 až 3 | 20 | 0,7 | 650 | < 200 °C |

| CrCN – L | 22 | 0,3 | 600 | ||

| CrTiN – L | 20 | 0,5 | 650 | ||

| CrTiCn – L | 22 | 0,35 | 500 | ||

| TiCN – L | 25 | 0,2 | 400 | ||

| TiN – L | 23 | 0,45 | 600 |

COMPOSITE HIGH-TEMPERATURE RESISTANT COATS KTRN

New composite coats based on Al, Ti, Si, Nb and Cr produced by new ARC technology, reach heat resistance against oxidation up to 1000°C. The hardness reached is about 3500 HV and adhesion of coats is 100 – 120N. These coats are intended mostly for cutting tools (drills, milling cutters, shank tools, cutting tips) of sintered carbides working under conditions of high cutting speeds.

The mechanical properties of composite coats were measured at Department of solid substances physics of Comenius University in Bratislava and operating life tests were performed at own facilities using the CNC milling machining centre CINCINATI MILACRON. Cutting tips from SANDVIK COROMANT company were used as the testing tools, which were deposited by various kinds of coats. The ratio of cutting edge wear to the length of cut was measured. Material used for machining was the tool steel acc. to STN 419436 hardened to 30 HRC. Speed of 1300 rev/min, stock removal of 2 mm and feed of 0,2 mm.

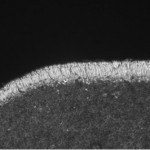

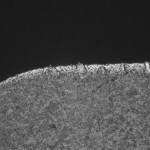

The following picture show comparison of cutting edge’s wear for two different coats – TiAlN and KTRN

TiAlN after 3 m cut (x100) KTRN after 8 m cut (x100)

Contact

Staton s.r.o.

Sadová 1148

038 53 TURANY, Slovakia

Tel.: +421 43 4292362

Tel.: +421 43 4292638

Fax: +421 43 4292585

Staton s.r.o.

Stahlkonstruktionen

www.statonsk.eu