Rectification

Rectification or rounding of cutting edge is relatively new term in tooling practice. Its use started only together with introduction of coating and coating equipment.

Operation of rectifying (rounding) the cutting edge is a special modification of the cutting edge and tool surface after grinding before coating.

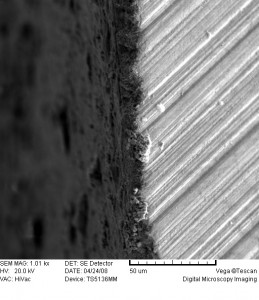

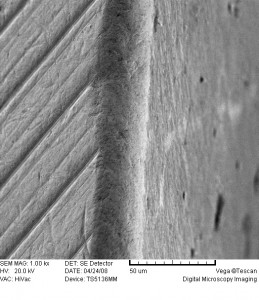

Cutting edge before rectification Cutting edge after rectification

The grinding leaves on cutting edges burrs, crumbled micro-surfaces and traces after grinding wheel, which impair cutting edge. By means of rectification – controlled tumbling and polishing in special abrasives, the unevenness is removed and cutting edges are rounded.

This modification strongly improves the quality of tool surface before coating and increase the adhesion of coat. The tool surface after grinding may be polished to the mirror finish.

STATON company performs the rectification of cutting edges using the machine from German manufacturer OTEC.

Contact

Staton s.r.o.

Sadová 1148

038 53 TURANY, Slovakia

Tel.: +421 43 4292362

Tel.: +421 43 4292638

Fax: +421 43 4292585

Staton s.r.o.

Stahlkonstruktionen

www.statonsk.eu