Vývoj a výskum

Udržať vysoké tempo inovačných zmien a nestratiť kontakt s konkurenciou. To sú hlavné priority firmy STATON v oblasti výskumu a vývoja, ktorý smerujeme najmä do povlakovacích zariadení a vývoja nových typov povlakov.

Technológie PVD – povlakovania za nízkych teplôt (už okolo 160 – 180 °C) vďaka vysoko ionizovanej plazme rozširujú možnosti využitia povlakov kovových materiálov do nových oblastí. Tiež neustály a stále sa zrýchľujúci rozvoj nanotechnológií má podporný účinok v inováciách tak v materiáloch, ako aj v povrchových úpravách.

Heslom doby je nezaspať na vavrínoch. Aj preto sa my v STATONE snažíme rozvíjať spoluprácu s univerzitami a výskumnými pracoviskami. A nielen to, sami sa tiež zapájame do výskumných aktivít a podporujeme výskum a vývoj napríklad formou výstavby nového vysunutého pracoviska Univerzity Komenského v priestoroch areálu firmy STATON v Turanoch. Výstavba a uvedenie do prevádzky by sa mali zrealizovať v priebehu roku 2013.

Research

Scientific-Implementation Workplace of Comenius University in Bratislava and STATON, s.r.o. located in Turany represents over twenty years of research collaboration in deposition of wear and abrasion resistant hard coatings on tools and tribological protective coatings on bearings using advanced PVD (arc evaporation and magnetron sputtering) and PECVD (Plasma Enhanced Chemical Vapor Deposition) deposition techniques.

Researchers and valued employees have many years’ experience in the fields of mechanical engineering, electro engineering, material science, thin films and physics of plasma.

The design and construction of proprietary deposition machines together with research and development of novel types of nanostructured and nanocomposite coatings with superior quality is especially important for us and represents the core of our service for customers.

Description

We are always keen to learn new promising approaches and improve the quality our products. Recently, we have implemented the novel techniques of HiPIMS (High Power Impulse Magnetron Sputtering) and HITUS (High Target Utilization Sputtering) for deposition of coatings of new generation.

The laboratory focuses in the research and development of novel plasma technologies and characterization and analysis of the deposited coatings. Properties (e.g. hardness, coefficient of friction, adhesion, thermal stability, etc.) and performance of coatings strongly depend on the structure, composition and the coating method used. These can be precisely measured in our Workplace which is very well equipped with the state-of-the-art analytical devices.

Analysis and characterization of coatings

- Chemical composition (EDS/WDS, GDOES, XPS)

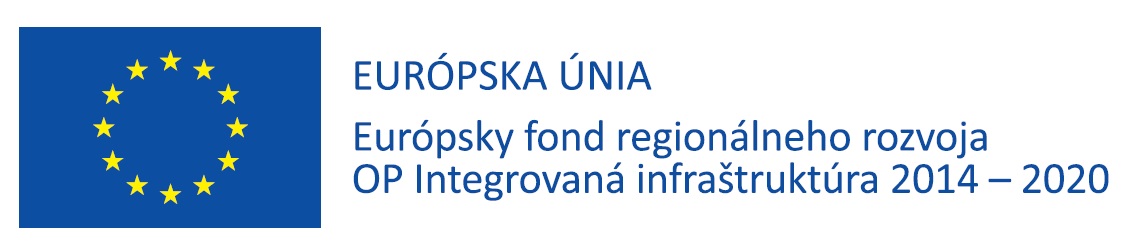

- Coatings morphology and cross-sectional imaging (SEM/FIB)

- Structure and phase evolution (High-temperature XRD up to 1100°C)

- Thickness (Calotest)

- Adhesion (Normal force up to 200 N)

- Hardness and Young´s elastic modulus (nanoindentation)

- Coefficient of friction and wear resistance (ball-on-disc tribometer up to 1000°C)

- Surface roughness (non-contact interferential profilemeter)

- thermal stability (furnace up to 1600°C in vacuum or inert/air environment

Examples of coating analyzes performed through collaboration between Comenius University in Bratislava and STATON,s.r.o.

Projects

2017 – 2023 “Research Centre of progressive materials and inovative technologies based on nanostructured coatings for technical and biomedical applications” project in the frame of Operation program Research and Innovation. Applicant: STATON,s.r.o., Partner: Comenius University in Bratislava

2012-2014 “Plasma Technology Research and Development Centre in Turany” project in the frame of Operation program Research and Development ITMS: 26220220166. Applicant: STATON,s.r.o., Partner: Comenius University in Bratislava

2012-2014 “Modernization of the scientific-implementation workplace” project in the frame of Operation program Research and Development ITMS: 26210120010. Applicant: STATON,s.r.o, Partner: Comenius University in Bratislava

2009-2012 “Universal experimental plasma equipment” project in the frame of Operation program Research and Development ITMS: 26220220004. Applicant: Comenius University in Bratislava, Partner: STATON,s.r.o.

Certificate of STATON,s.r.o. company´s capability to conduct Science and Research issued by the Ministry of Education, Science, Research and Sport of the Slovak Republic.

Certification

Our company has many years’ experience with industrial production and solving of complex European projects. We know that quality is always at the top of the list of requirements. We take great care about quality of our products, services and other outputs. This approach has resulted in acknowledgement of STATON,s.r.o., by several quality management system certificates:

ISO 9001:2008 – scope numbers:

17 – Production, grinding and coating of the cutting tools

34 – Welded constructions

35 – Research and development in the fields of natural sciences and engineering

STN EN 15085-2:2008

– certification level CL 2 – Welding of railway vehicles and components

![]()

Certificate AS9100

Certificate EUTM 018561322 Nano Pag STATON

Certificate EUTM 018561324 Plasma AG Staton

Kontakt

STATON, s.r.o.

Sadová 1148

038 53 TURANY, Slovensko

email: staton@staton.sk

Tel.: +421 918 320 177

Tel.: +421 43 4292362

Tel.: +421 43 4292638

Fax: +421 43 4292585

Staton s.r.o.

oceľové konštrukcie

www.statonsk.eu